| Have any questions? Our experts are here to help. Call Us (480) 447-4184 |

Cribbing serves as a fundamental component in modular logistics as the predominant storage methodIts primary function is to offer stable and level support for modules whether at the factory or staging/storage yard. This support system is essential to prevent any movement, shifting, or tipping during assembly or storage, ensuring the safe and secure handling of these modular components at every stage of the unloading and loading process. With numerous cribbing materials available for modular applications, determining the ideal choice can be challenging. Here is what we discovered.

| Have any questions? Our experts are here to help. Call Us (480) 447-4184 |

Cribbing is a temporary structure, like jack stands, that supports heavy freight — such as modules — during storage. It stabilizes and levels the modules to prevent shifting, tipping or other movement that could damage the mods before reaching the construction site.

Made from sturdy material, often wood or steel, in a variety of shapes and sizes, cribbing can support modules in the factory as they await shipment, during transportation, and at the staging yard prior to assembly.

| Have any questions? Our experts are here to help. Call Us (480) 447-4184 |

Cribbing must be strong and durable to properly bolster modules and withstand the elements. Thus, it is most commonly made from wood, metal, or plastic. When considering alternative materials for cribbing blocks, it’s essential to assess the specific requirements of the application, including load capacity, environmental conditions, safety regulations, and cost-effectiveness. Consulting with experts or engineers in your industry can provide valuable insights and recommendations for the most suitable material choices for your specific needs.

| Have any questions? Our experts are here to help. Call Us (480) 447-4184 |

Cribbing blocks adhere to a range of sizes and shapes. These designs emphasize a flat and stable surface, ensuring uniform weight distribution and preventing any shifting, thereby safeguarding the integrity of the stored or transported cargo.

| Have any questions? Our experts are here to help. Call Us (480) 447-4184 |

Ensuring the proper positioning of cribbing blocks is of upmost importance in the realm of modular transport handling. It is imperative to strategically distribute the module’s weight evenly across the surface. These blocks not only provide support to prevent undue stress on the cribs, but also safeguard specific areas on the module’s frame, maintaining stability throughout the process. It is essential you adhere to industry standards and guidelines for cribbing techniques for safety. This will guarantee the secure and efficient handling of your sizable loads.

| Have any questions? Our experts are here to help. Call Us (480) 447-4184 |

Outdoor staging yards come with their own unique set of challenges. From unpredictable weather conditions to ever-changing terrain, maintaining module stability is crucial. That is why it is important to choose durable, high-low bearing cribbing that can stand up to the elements and provide stable support to your mods. Discover more about the various cribbing options tailored for outdoor staging yards below.

Wood cribbing is a good choice for cribbing material for several reasons. First, it is more cost-effective than using steel cribbing, making it a more budget-friendly option. Depending on current lumber prices, an 18”x18”x39” crib contains about $50-60 of material costs, plus some labor costs. Second, wood has a high load-bearing capacity which means it can support heavy loads effectively. Additionally, wood’s versatility also makes it a good choice for cribbing material as it can be easily cut, shaped, and customized to meet specific requirements, enhancing its adaptability.Wood is also readily available, making it a convenient and accessible choice for cribbing needs.

While wood cribbing offers advantages like affordability, and versatility, it also comes with limitations. It has a lower load capacity compared to materials like metal or steel. Additionally, wooden cribbing blocks cannot stack within themselves, leading to increased storage space requirements and higher transport costs. Furthermore, wood cribbing is prone to wear and tear, especially in outdoor environments. The cost benefits are negated by the fact that they do not last long and require replacement fairly regularly.

When considering metal options for cribbing blocks, steel is the most common and recommended choice. Steel cribbing is easily customizable, allowing for maximum space below modules, facilitating the backing up of trailers underneath for efficient loading and transport. Moreover, steel cribbing offers exceptional load-bearing capabilities, ensuring the secure support of modules even under heavy loads. Its high durability and resistance to extreme conditions make it a reliable choice, ensuring long-lasting performance. Additionally, within the steel category, various types and grades are available, providing flexibility and adaptability to meet specific cribbing requirements. Overall, steel cribbing, with its strength, durability, and load-bearing capacity, emerges as a better choice than wood for supporting modules in cribbing applications.

However, steel cribbing, while offering numerous advantages, presents some drawbacks. Cribbing made from steel is typically heavy like wood making it difficult for a single person to handle. Additionally, steel cribbing tends to be pricier than wood cribbing and has longer production times compared to other materials like wood. It’s also susceptible to corrosion, requiring maintenance and protective measures. Lastly, they don’t stack or nest well, requiring more space for storage and transport.

With our experience in modular transportation logistics, we’ve worked with various cribbing materials, like wood and steel. However, we believe a new product will emerge as the bonafide best option: ModCribs, which combines the benefits of both wood and steel, while addressing their weaknesses. Made from cast-molded structural foam, ModCribs are extremely durable and lightweight. In fact, they weigh just 28 pounds, and have an individual weight rating of 10,000 lbs. In contrast, steel and wood modules are often over 100 lbs. ModCribs are also stackable, allowing 1,000 ModCribs to be transported on a single truckload compared to 200 wood cribs. This means better cost efficiency and time management for large modular projects. In summary, ModCribs are lighter, more durable, and have the unique benefit of being stackable, making them our recommended choice for your projects. Visit ModCribs.com to find the perfect fit for your modular transportation projects.

The types include blocks or stands made out of a sturdy material - such as wood, steel or plastic - to support and stabilize modules in the factory or staging/storage yard setting.

Primary purpose is to provide stable and level support for modules that are being placed temporarily to prevent any movement, shifting, or tipping during the assembly or storage stages.

Wood is the most common choice for cribbing material due to its strength, durability, affordability, and wide availability. Wood is a renewable resource with shock-absorbing and non-conductive properties. Plus, this versatile material can be easily cut to make cribbing blocks of various shapes and sizes.

Strong and durable hardwood such as oak is ideal wood cribbing for heavy loads. But lighter, flexible woods like Douglas Fir, which creak and give warning when overloaded, offer an extra level of security when the load capacity is unknown.

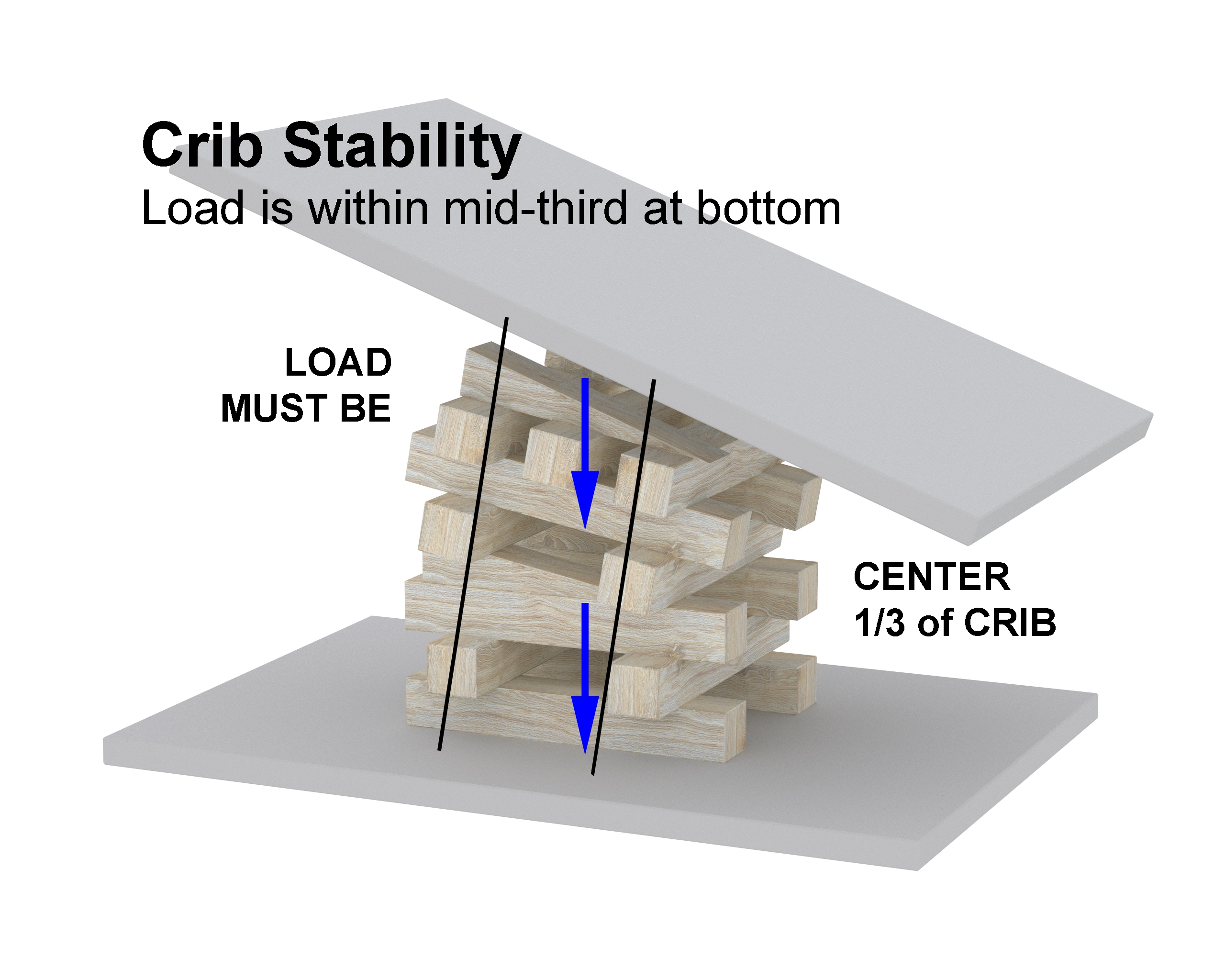

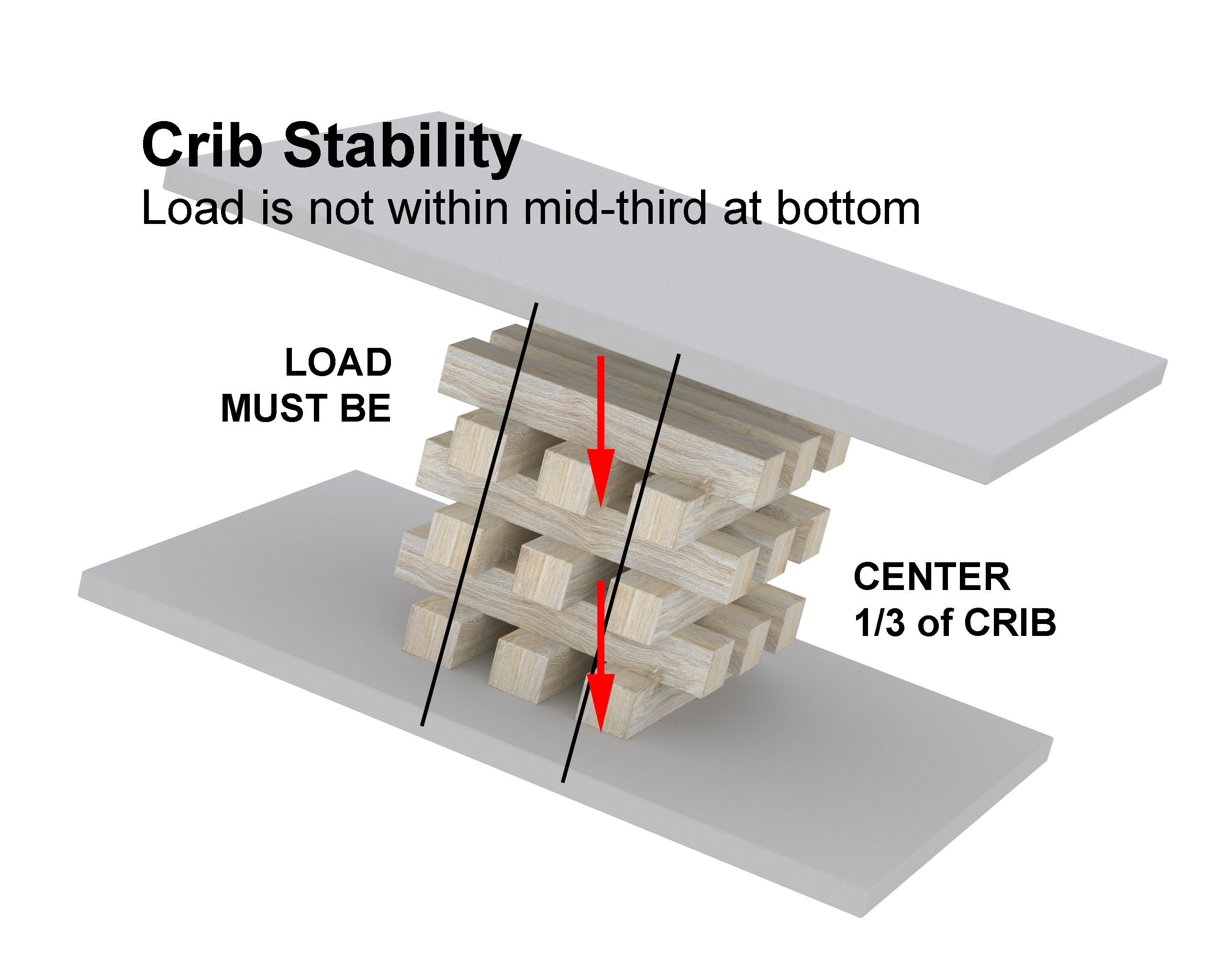

Design: The height of box cribbing should not exceed 2x the working width of the base of the box crib. Example: 18’’ cribbing = 36’’ box crib height

Steel, is another popular cribbing material thanks to its high durability, structural integrity, resistance to fire and chemicals, and ease of storing. The stand design provides the most room under and between modules, allowing carriers and equipment to lift from underneath. Further, steel cribbing blocks can be manufactured with precise dimensions and tolerances, allowing for accurate stacking, interlocking, and alignment — and thus enhanced stability.

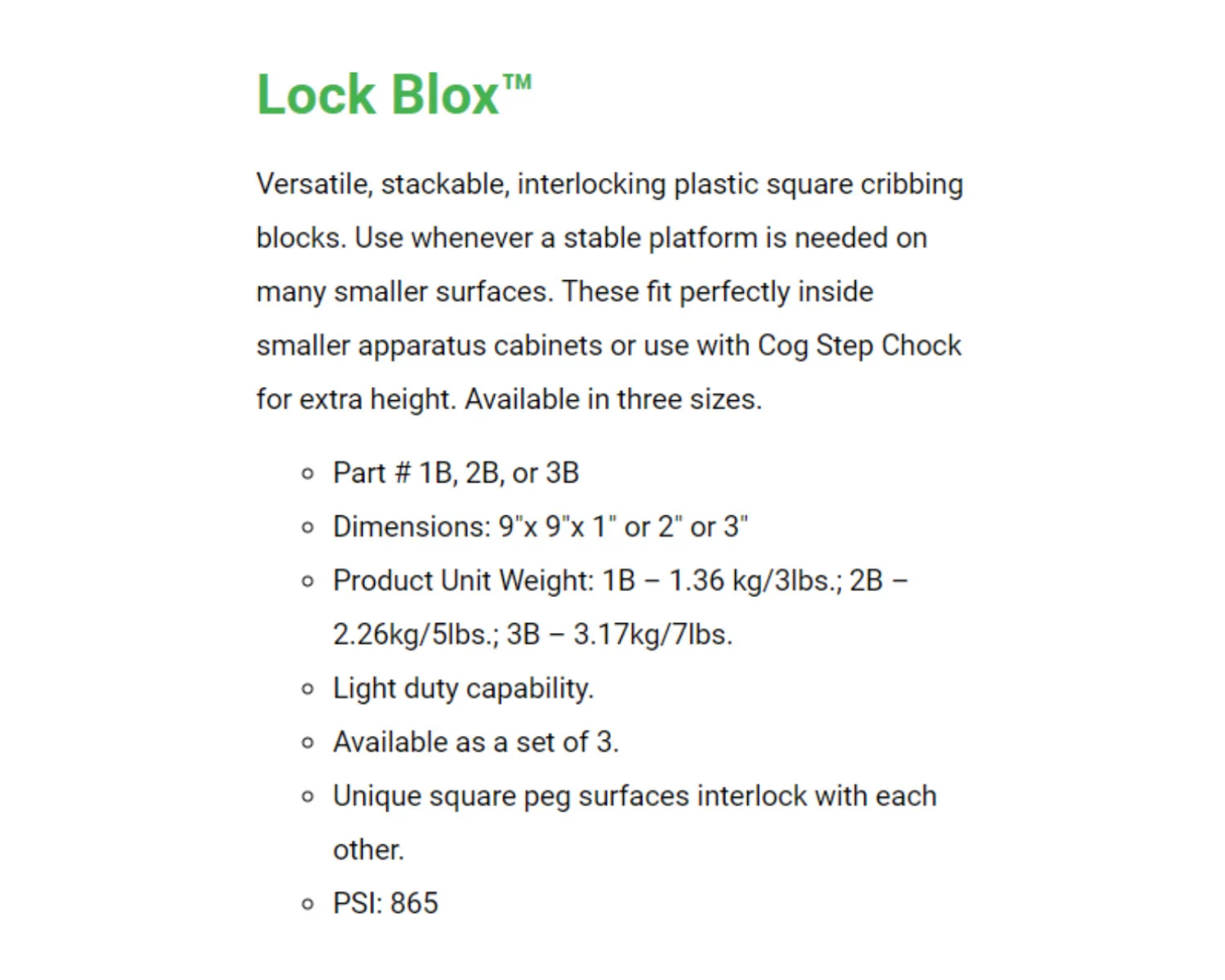

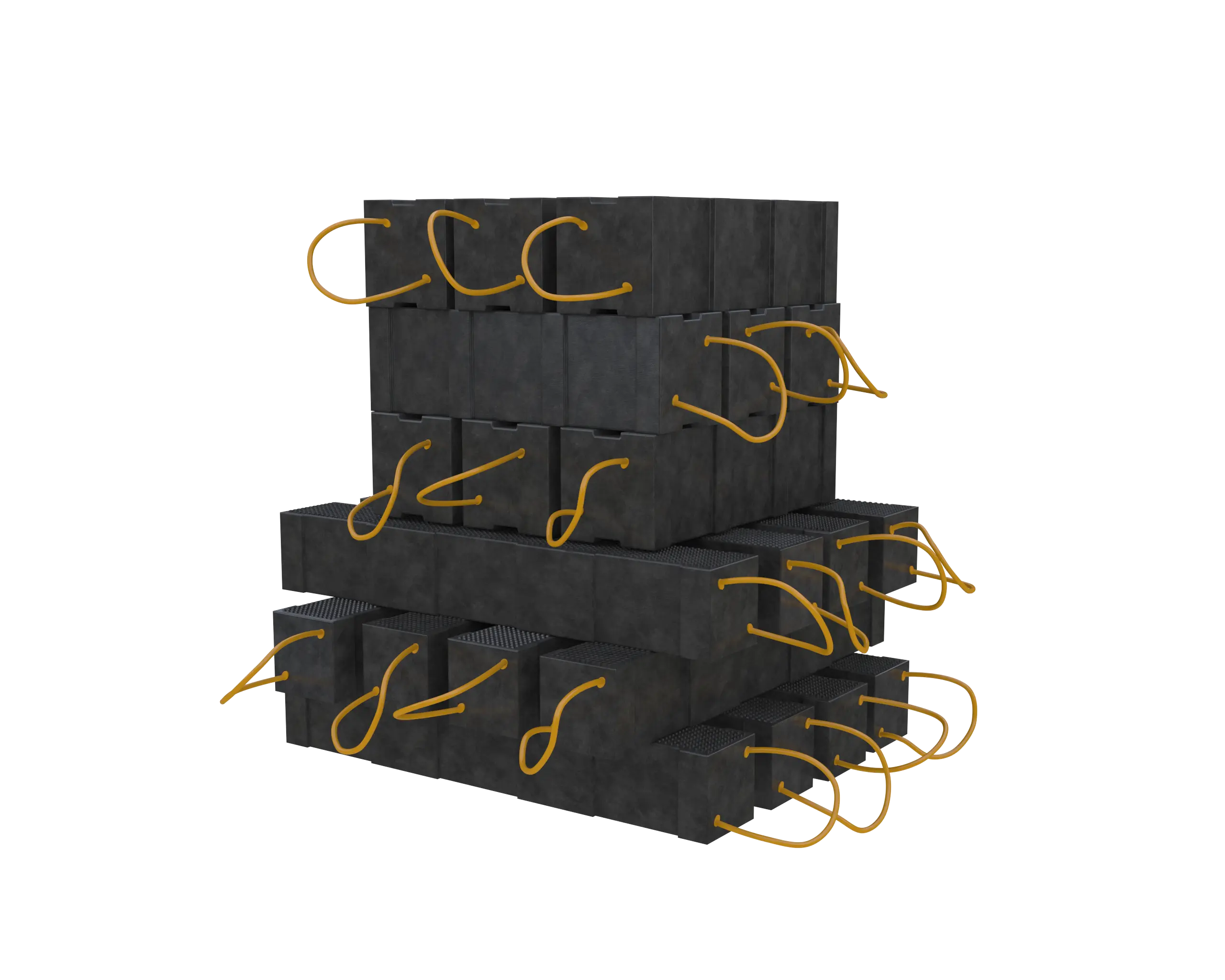

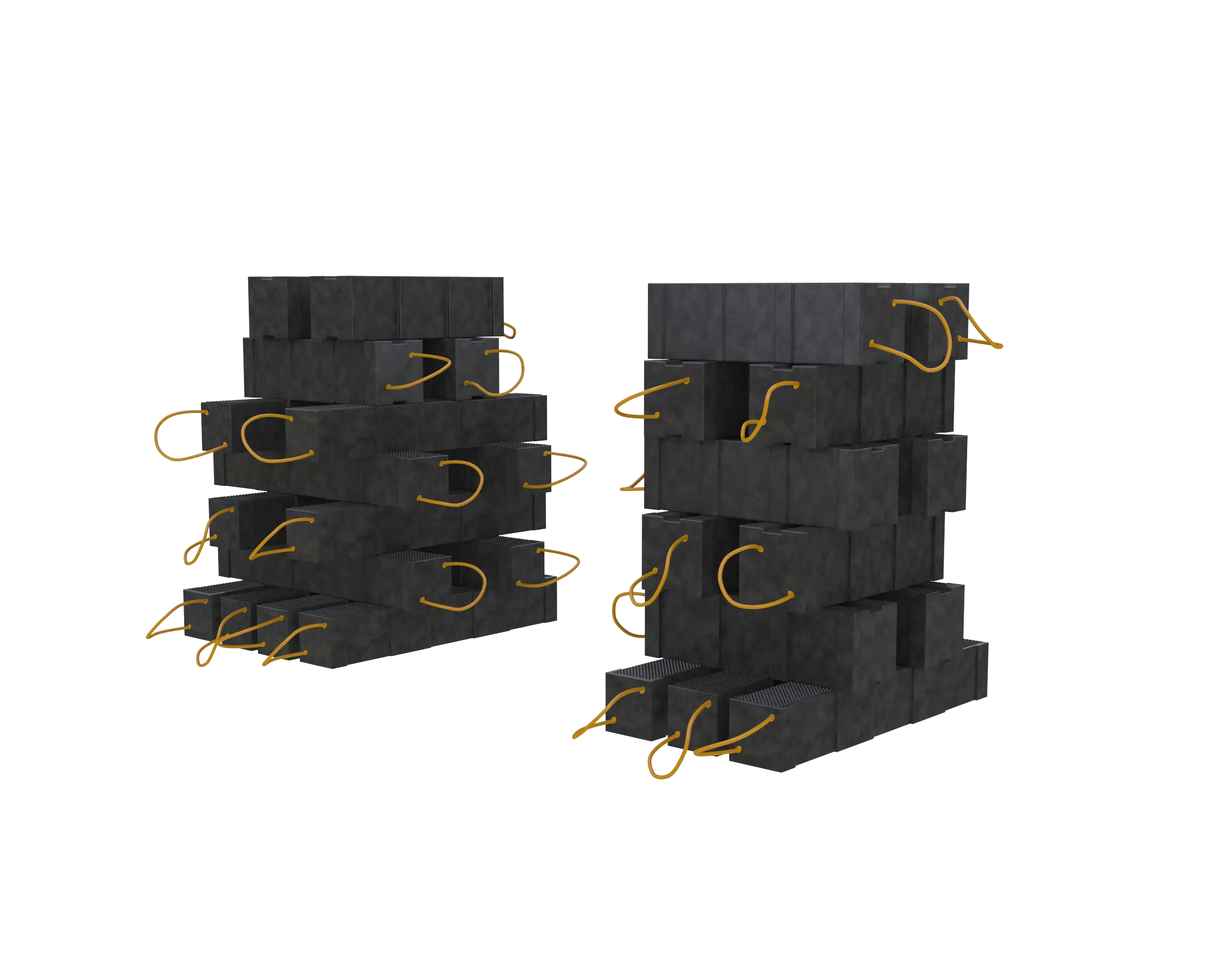

Suitable for electrical or marine environments, high-density plastic is lightweight, resistant to moisture and chemicals, and non-conductive. Plastic cribbing is versatile, stackable, and interlocking, and it comes in nearly every shape and size. And, when it comes to withstanding the elements, it won’t crack and splinter like wood or corrode like metal.

| Pro Tip! | Important to note: When considering alternative materials for cribbing blocks, it’s essential to assess the specific requirements of the application, including load capacity, environmental conditions, safety regulations, and cost-effectiveness. Experts or engineers in your industry can provide valuable insights and recommendations for the most suitable material choices for your specific needs. |

This type of cribbing is a combination of resins, fibers, and additives. They provide support by using high strength-to-weight ratios, are resist to corrosion and have enhanced durability compared to wood.

Cribbing blocks come in various sizes and shapes, but they are often rectangular or square with a flat surface for stability. The box crib is most common: It is constructed by arranging sets of matched blocks made of wood or steel in a regular log-cabin style to form a rising square or rectangular frame.

There are occasions where triangle cribbing or custom cribbing is most appropriate. In any cribbing method, it’s important that each block or stand is cut and shaped with precision to ensure a secure and uniform fit when arranged and stacked together.

When it comes to size, While there are no specific “ideal” dimensions for cribbing blocks, a common size range for industrial applications is around 6 inches to 12 inches (15 cm to 30 cm) in length, width, and height. The height of box cribbing should not exceed two times the working width of the base of the box crib. Generally, you should consider the block’s height and weight, stability, thickness, material strength, and stackability when determining the optimal size of the cribbing block.

Note: It is important to consult industry standards, guidelines, or engineering professionals for specific recommendations based on the load requirements and safety regulations in your industry.

| Pro Tip! | Remember, when using design plans for cribbing blocks, it is crucial to adapt them to the specific requirements and load conditions of your application. Local regulations, safety codes, and site-specific considerations should also be taken into account. |

Properly designed and implemented cribbing blocks, whether made of steel, plastic, or wood, provide stable support for modules. When used correctly, they minimize the risk of modules shifting and falling.

First and foremost, ensure that you have enough cribbing, which is typically based on the length of your module. You’ll also need a certain amount of strategically placed, evenly distributed cribbing points so the mods can’t rock or, worse, fall.

Position cribbing blocks to evenly distribute the weight of the module or equipment. This helps maintain stability and prevents excessive stress on specific areas of the structure.

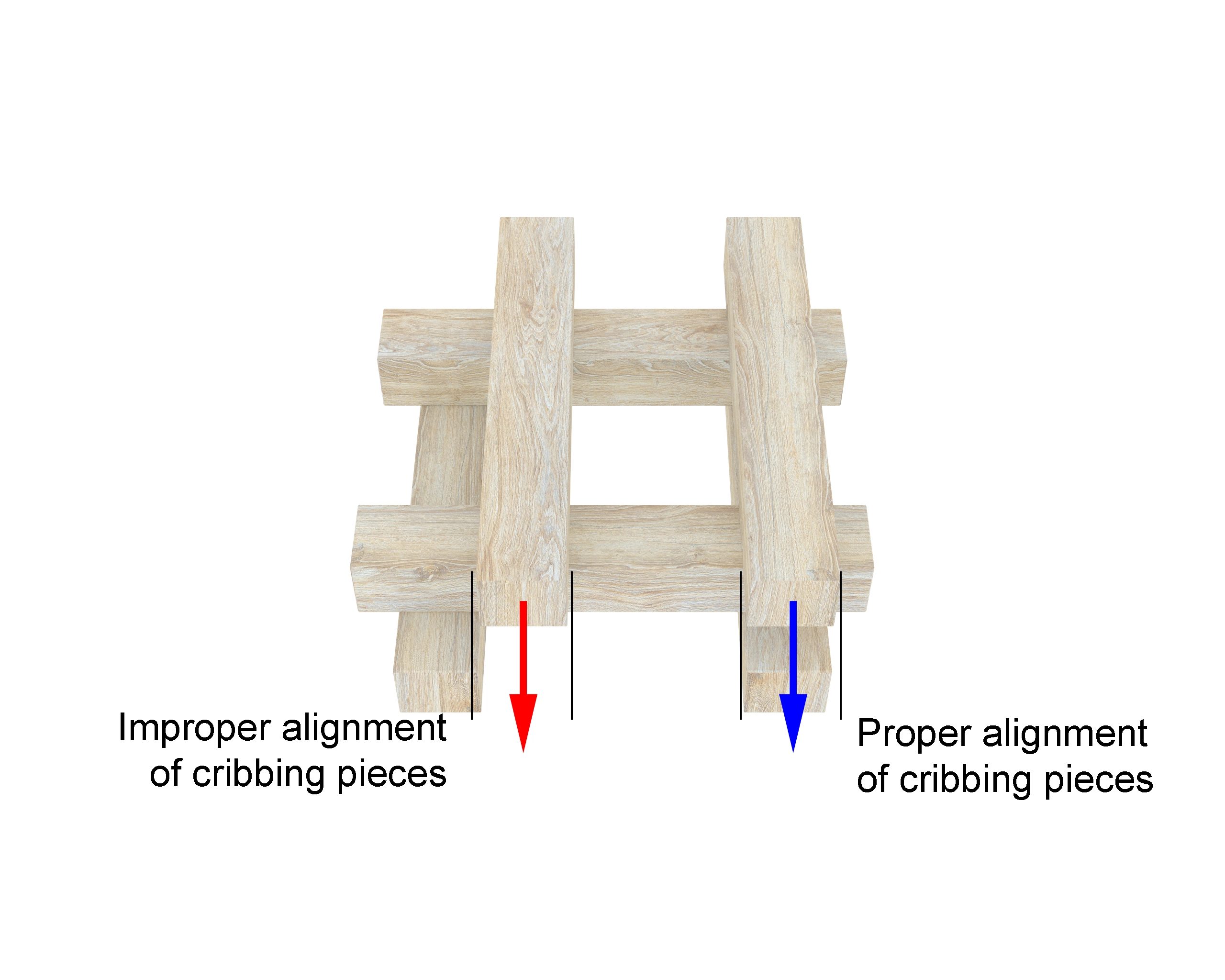

Properly align, stack, or arrange cribbing to prevent slipping, shifting, or toppling. They may have interlocking features or beveled edges to enhance stability.

Stack or arrange cribbing to provide a level and appropriate height for the module. Uneven or unstable support can increase the risk of instability or tipping.

Understanding and considering the module’s center of gravity is crucial for proper cribbing. Placing the blocks strategically to support the module’s center of gravity helps maintain stability and balance.

Environmental conditions such as vibrations, wind, seismic activity, or uneven ground can impact module stability. It’s important to assess and mitigate such factors to minimize the risk of instability.

Keep in mind, with time and use, cribbing can wear, deteriorate, and suffer damage. Regular inspections of cribbing are critical to ensuring their structural integrity. You should promptly address or replace damaged blocks or modules to ensure safety

While the suitability of cribbing blocks in an outdoor staging yard environment depends on various factors, there are some types of cribbing blocks that may have limitations or be less ideal for such conditions. Here are a few examples:

Softwoods, such as pine or spruce, are generally less ideal for outdoor staging yard environments due to their lower resistance to moisture, weathering, and decay. Softwood blocks may be more prone to warping, cracking, or rotting when exposed to outdoor elements, which can compromise their stability and durability.

While steel cribbing blocks are generally suitable for outdoor use, uncoated steel blocks may be prone to corrosion when exposed to moisture, rain, or harsh weather conditions. Corrosion can weaken the blocks over time, compromising their structural integrity and load-bearing capacity. To mitigate this, using steel blocks with appropriate corrosion-resistant coatings or finishes is recommended for outdoor environments.

Cribbing blocks made from treated wood, such as pressure-treated wood, may not be the best choice for outdoor staging yards, particularly in environmentally sensitive areas or where chemical leaching could be a concern. The chemicals used in the treatment process can potentially leach into the ground or affect surrounding vegetation and wildlife.

Lightweight or thin gauge cribbing blocks, whether made of metal or other materials, may have limitations in outdoor staging yards. They may lack the necessary strength and stability required to withstand the dynamic and unpredictable conditions of outdoor environments.

| Pro Tip! | Remember, when using design plans for cribbing blocks, it is crucial to adapt them to the specific requirements and load conditions of your application. Local regulations, safety codes, and site-specific considerations should also be taken into account. |

The outdoor staging yard environment introduces additional challenges — including weather and variable terrain — to keeping modules stable. Thus, it is important to choose durable, high-load-bearing cribbing that can withstand exposure to the elements and provide stable support. Types of cribbing blocks common for outdoor staging yards include:

Concrete is durable, weather-resistant, and can withstand exposure to sun, rain and temperature fluctuations. Concrete cribbing blocks have high load-bearing capacities and are available in various sizes and shapes, allowing for customization based on specific terrain.

Polypropylene cribbing blocks are resistant to moisture, chemicals and UV rays, making them durable in outdoor environments. Lightweight but with high strength-to-weight ratios, they are easy to handle and transport.

Steel cribbing blocks are strong, stable and durable with the ability to withstand outdoor conditions and provide reliable support for heavy loads. Corrosion-resistant coatings or finishes can enhance the steel blocks’ weather resistance.

Rubber or anti-slip cribbing blocks have extra grip and stability that help minimize the risk of movement and slipping in wet environments or on uneven surfaces.

Adjustable height cribbing blocks, such as screw jacks or telescopic columns, allow for precise height adjustments, which is ideal for leveling or supporting modules or equipment on uneven surfaces.

| Pro Tip! | In an outdoor staging yard, avoid types of cribbing blocks that do not tolerate moisture, such as softwood blocks or uncoated steel blocks. Steer clear of treated wood blocks, which may cause chemical leaching and harm local vegetation and wildlife. Lightweight or thin gauge blocks are also not suitable for staging yard environments due to limited load-bearing capacity and stability. |

Remember that the specific practices and guidelines for cribbing in staging yards may vary depending on the industry, regulations, and site-specific requirements. It’s important to consult and follow the recommendations and safety guidelines provided by experts in your specific field or industry.

| Want to learn more about cribbing and the secure transport of modules? Reach out to our team to get the conversation started. | Contact Us |